WE SURPASS THE ORDINARYAND THRIVE ON WHAT’S NEXT.

OUR SERVICES

ASTOUND's state-of-the-art fabrication facilities and in-house team of experts make the impossible possible. Partnering with GCs, design firms and brands we fabricate and install complex architectural projects around the world.

WHAT WE DO BEST

Complex Structural Solutions

Architectural Features

Retail Fixtures

Retail Manufacturing

Public Art

Sculpture + Props

Custom Corian Furniture + Counters + Features

Complex Wall Panels

Thermoforming

Ceiling Features

Custom Digital Integration

Projection + LED Mapping

Schematic + Detail Design

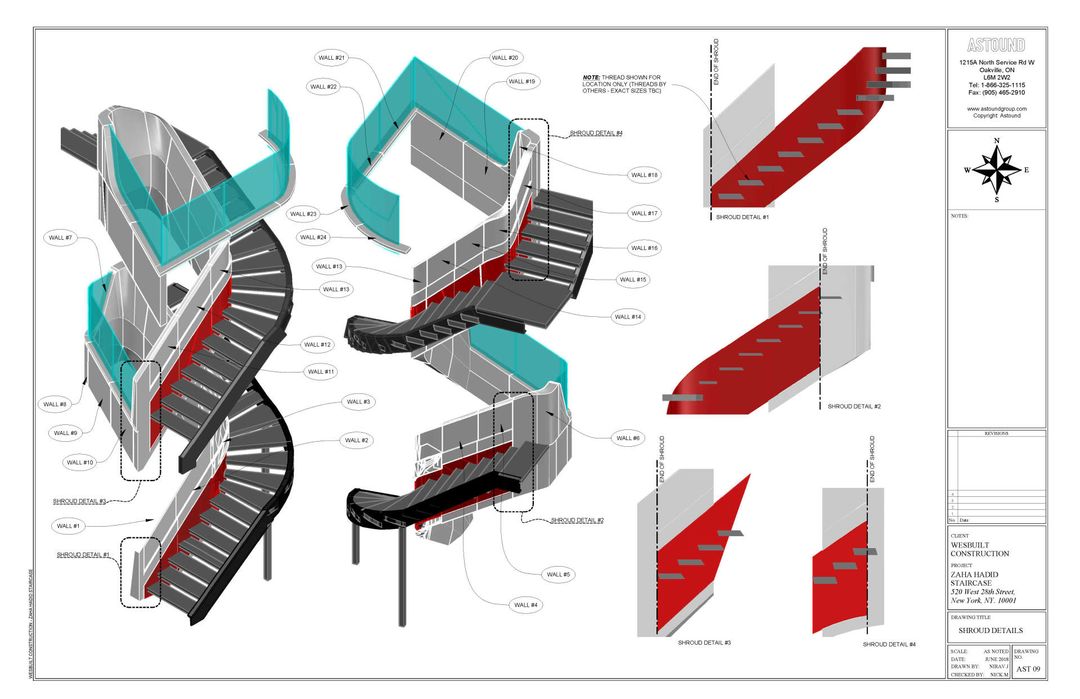

The digital fabrication team works with the latest technology and machinery to produce highly complex and precise components. Our development teams work with digital software to develop 3D models that are exactly what will be fabricated. These models are shared with the project teams to assist in coordinating on-site integration and other elements within the environment. The models and files are then sent to our digital fabrication equipment to fabricate highly complex work with speed, precision and quality in mind.

Any successful build begins with a strong core. In the permanent and architectural fabrication world, that strong core typically starts as an engineered metal sub-structure. Our metalwork shop team works hand-in-hand with our digital fabrication and detailing departments to ensure the accurate understanding of the project which, in turn, leads to an efficient and smooth production process. The metalwork department handles a variety of custom projects from public art to residential features using almost any material available from aluminum to steel and everything in between.

KEY TOOLS OF OUR TRADE

Digital Press Brake, 5-Axis Water Jet, MIG / TIG / ARC Welding, Plasma Cutting, Bending & Forming

VIEW PROJECTS

With decades of experience in wood and composites, premium quality is standard procedure for the millwork fabrication team. Our in-house craftspeople bring a wide range of experience to the shop with everything from cabinet and casemaking to complex public artwork and permanent architectural features for the likes of Zaha Hadid and Bjarke Ingels. Our highly skilled project design and detailing department is responsible for reverse and value-engineering and developing highly detailed production drawings that allow our craftspeople and artisans fabrication all the necessary components while staying as true to the design as possible.

The custom finishing adds the final touch to take all our projects to the next level. During the project development process, we work closely with our clients to identify materials and finishes that achieve the desired aesthetic and durability. Any considered finishes and materials are tested and reviewed closely by our clients and project managers for approval before final fabrication and finishing.

Our team of designers, developers and engineers can develop and integrate any type of electrical component from LED mapping and video projection to interactive displays and feature lighting. Interactive and electrical components can be as simple as features requiring manual input, or complex interactives activated by motion sensors or touch devices. Our team offers custom industrial design services to our clients for one-off or mass-produced items such as custom light fixtures, interactive displays and robotics.

KEY TOOLS OF OUR TRADE

LED Mapping, Projection Mapping, Custom Lighting, Interactive Displays

VIEW PROJECTS

Our team of best-in-class project managers partner with clients to bring the most complex ideas through to fruition on time and on budget. Every project is assigned a dedicated project manager who is responsible for seeing the project through to final installation. Your project manager will manage all aspects of our scope and assemble a team specific to your requirements. Updates on progress, timelines and budgets will be shared throughout the lifecycle of the project to keep all teams aligned

ASTOUND’s project developers immerse themselves in the design process and work with client teams to refine the concept and direction. We provide guidance on fabrication approach, material choices, details and finishes that will achieve your vision while considering timing and budget parameters.

Install is considered throughout the project life cycle to minimize time and maximize efficiency on-site. Close consideration of our scope and how it integrates with the rest of the install environment is crucial to every project. ASTOUND leverages technology using 3D site scanning services to fully understand the installation environment in preparation for project deployment. All project components within our scope are fabricated and assembled offsite to minimize load in effort and install time and allow for high precision tolerances and quality control.